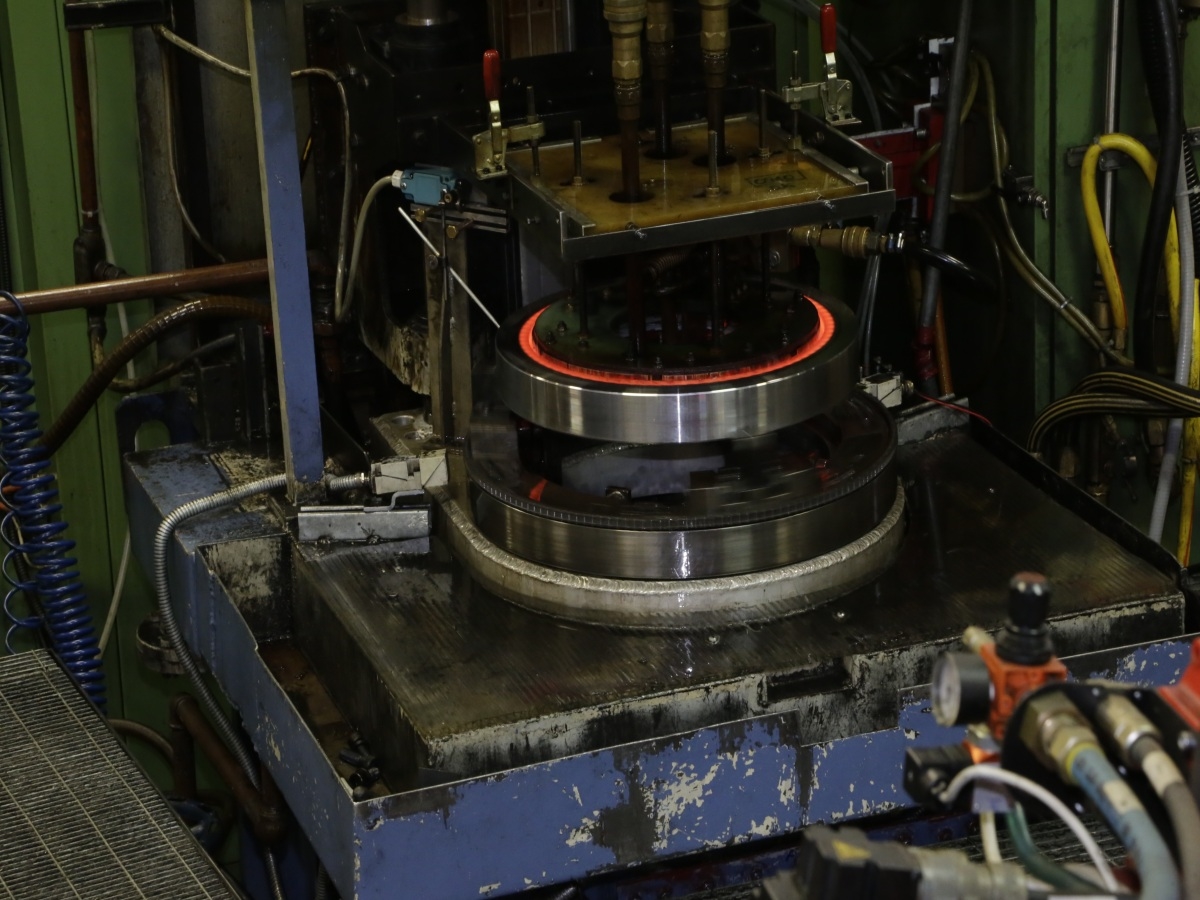

The surface hardening heat treatment is used to increase wear resistance, surface hardness and fatigue strength of the piece, through the creation of a hardened surface layer, maintaining unaltered the microstructure of the core of the piece itself. In this process is used a coil on which alternating current is applied. This induces an alternating magnetic field inside the piece which generates passive electric currents that, for resistance effect, causes the piece to heat up to a temperature higher than the transformation one. Cooling (quenching) in polymers (Water - Quench) or oil is called “quenching”. Subsequently a tempering at low temperature also called "distension" is performed.

DEMM systems are equipped with water-quench and oil cooling, with manual and automatic loading.

Inductor size up to 500 mm.